Rack Mounting FAQ

10-inch half rack (10" rack)

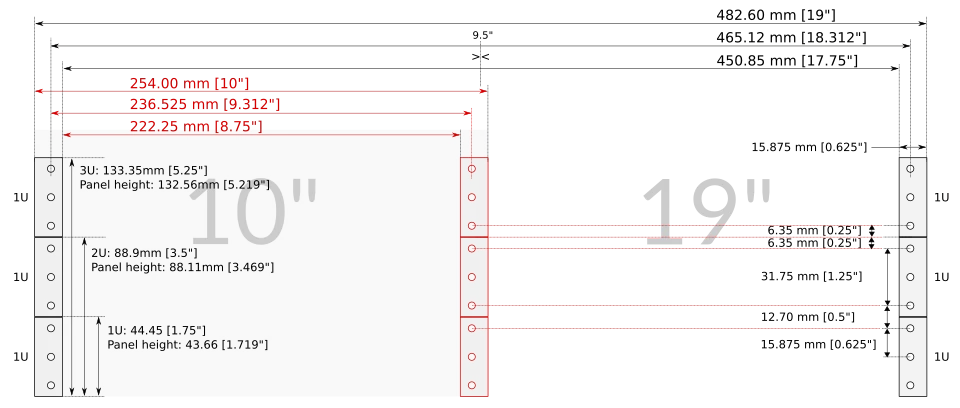

While it is common to use one 19" rack unit for two devices side-by-side, dedicated less-wide racks (more or less 10" wide) are finding their way into commercial installations, into SoHo and even military contexts, as stationary racks in airborne or otherwise weight or space constrained scenarios and as rugged shock proofed mobile crates for field deployed IT or radio equipment.Regarding IT deployments, a rack of exactly 10" is more and more becoming an industry standard for smaller computing and networking equipment in recent years. Although often referred to as being a "half-rack", a 10" rack is not a "real" half rack, as it is a little narrower. 10-inch rack dimensions are: exactly 10" (254.00mm) from side to side horizontally (front plate), including screwing area. Actual usable width is 8.75" (222.25mm) clear area in-between vertical screwing rails ("rack opening" or "aperture"). 10" and 19" racks use mounting rails of the same width, 0.625" (15.875mm). Analog to the EIA 310 19" rack, the actual depth of racks is undefined, but 10 inch racks are usually less deep in comparison to common 19" server cabinets, following the overall smaller footprint. The 10" rack layout is popular in SoHo, commercial and mobile installations where space is scarce or a less industrial looking furnishing is wanted. While dedicated 10-inch switches, 10-inch hubs and 10" computer enclosures are available, users often install consumer routers or similarly small devices in 10-inch racks in a DIY fashion on 10-inch rack shelfs or by using custom 3D printed brackets. Audio devices like microphone receivers, tone generators and effects processors use a 10"-similar half-width rack format, the 9.5" footprint, for decades. And although 9.5" half-rack devices (which are usually between 8.2" and 8.7" wide, often on the narrower side) can fit a 10" rack just fine, some vendors offer 10.5" racks, with a slightly wider 264mm/266mm to 271mm/275mm front panel width and 249mm or a little more hole to hole distance. Interesting to note is that the 10" rack, to a certain degree, follows the nesting paradigm of computer form factors: the rack opening on a 10" rack is exactly 5U wide (44.45mm x 5 = 222.25mm). Given a rack offers matching horizontal mounting rails, it is possible to mount 5 1U 19" modules vertically in a 12U tall 10" rack.

10.5-inch half rack (10.5" rack)

The 10.5" rack is the "wider version" of a "half size" rack, despite the fact that 10.5" isn't half of 19 inches. The confusion probably stems from the fact that many don't realize that a 19" device, while having a 19" wide front-plate, including rack-ears, means that the device itself, behind the front-plate, is less wide and actually only at maximum 17.75" wide. So when equipment is labeled as being 19"/2 or 9.5", it means two of these device would fit the 19" rack aperture, side by side, and adding rack ears to such a pair would make them 19" wide. Essentially that means that a half-rack device is at max (17.75" / 2 =) 8.875" wide (450,85 / 2 = 225.42mm). Now, the EIA 310 19" standard even suggests devices should be a little less wide (17.625"), with many being between 15.5" - 17.5" wide (~400mm - 445mm, or 10U vertically). While the actual device footprint should be labeled as 8.8" or rounded to 8.5", the term "9.5 inches" is often used to refer to a half-rack width device. This is expressed decimally, as before, or with a fraction stroke, like 19"/2 or 19/2. However, neither the device alone nor its width with added rack ears is actually 9.5" wide.In reality, half-rack (half-width) devices or modules are typically only around 220mm wide, sometimes even slightly less. This allows two modules to be comfortly bolted together in the middle while still retaining room to attach rack ears on each side. However, neither half-size racks nor half-sized modules are standardized - which is problematic. Some manufacturers utilize the full 19" rack aperture (450,85 / 2 = 225.42mm), maxing out available space, while others design enclosures to fit custom shelf systems or make modules arbitrarily "a little smaller" to potentially fit side by side in a 19" rack. As a result, when you attach rack ears to just one of these devices instead of two, you end up with varying widths. Adding rack ears with 0.625" each to a maxed out half-aperture device would result in a module 10.125" wide. But, as said, most manufacturers usually offer modules a little less wide, to make room for bolting or a cage/ shelf system. This inconsistency led to confusion when vendors began offering racks designed to mount only a single device, as it was unclear how wide exactly rack flanges should be apart. This uncertainty, along with the minimal need to shave off fractions in an already small footprint, led to the "wider" 10.5" layout becoming popular in military applications and a de-facto standard in A/V contexts. The slightly wider half-rack allows for a bit of room on each side, enabling various half-width devices to fit onto generic third-party shelves in most cases.

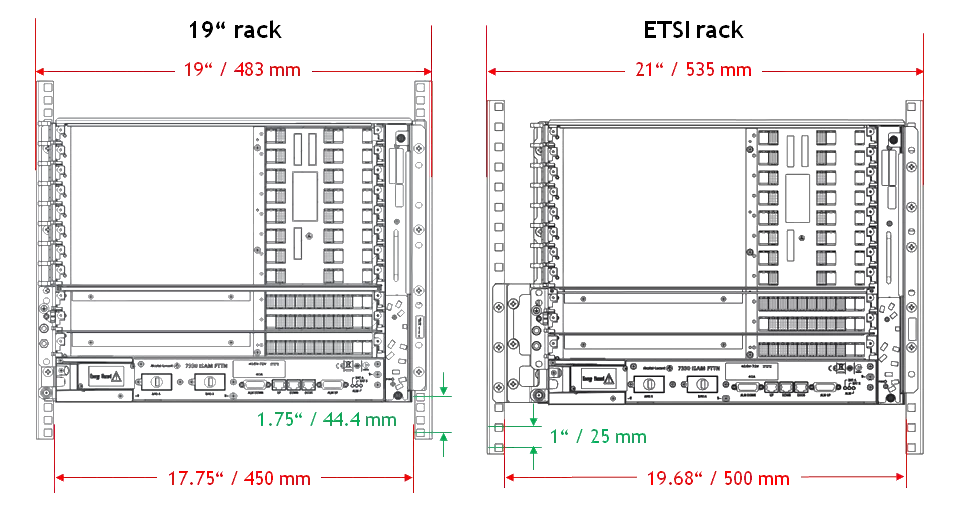

19-inch rack (19" rack)

is a standardized type of technical furniture, a frame or enclosure, of roughly 19" width for mounting multiple electronic equipment modules stacked over another on two parallel vertical rails. The "EIA 19-inch Standard Rack" (EIA-ECA 310E) is very common in scientific and computer / data-center environments. Actually, only the front plate of installed module measures 19 inches (482.60mm) wide, giving the name. Such a front plate is 19" (482.60mm) in total, including the screw terminal area, with 17.75" (17 3/4 inch, or 450.85mm) of clear area in-between vertical screwing rails (called "rack opening" or "aperture"), the actually usable space for mounted equipment between the mounting posts. 19" racks may be embodied as open frames, offering essentially vertical screwing rails only ("two-post racks", popular in telco applications) or as open or closed cabinets (usually 24" wide, 609.6mm), with optional additional internal width outside the rail area for more elaborate cabling.

Rack Flanges

Each EIA 310 compliant rack features at least two vertical beams (vertical "mounting flanges", "mounting posts", "uprights" or "rack rails"). These two posts are spaced 17.75" (17 3/4 inch, or 450.85mm) apart, building a "rack opening" and this is the space where installed equipment is residing in or in-between, the "usable aperture opening" or "rack aperture". The front of rack flanges is expected to be 5/8 inch wide (0.625" or 15.875mm), but the important dimensions are the clear area in-between flanges and the distance of the rack holes on the flanges center to center. On racks where the mounting flanges are a recessed element, with double-L shaped mounting rails or when the rack flanges are part of or installed in a closed rack cabinet, the EIA specs expect the available width for front panels (the "panel opening") to be at least 19" plus 1/16 inch (or 19.0625" or 484.1875mm) toleranced at 1/32". Suggestions for the maximum width of installed equipment in-between the posts (including any slides, rails or similar mounting helpers) varies between a suggested 17.625" (447.675mm) in imperial unit specs and of course the absolute ceiling value imposed by the defined 17.75" (17 3/4 inch, or 450.85mm) minimum rack aperture. It may be noted here that soft converted metric specs gave 450mm at one point in time, a little less, as the minimum space between rack posts, but read a little below for a note on this soft conversion process.Rack Holes

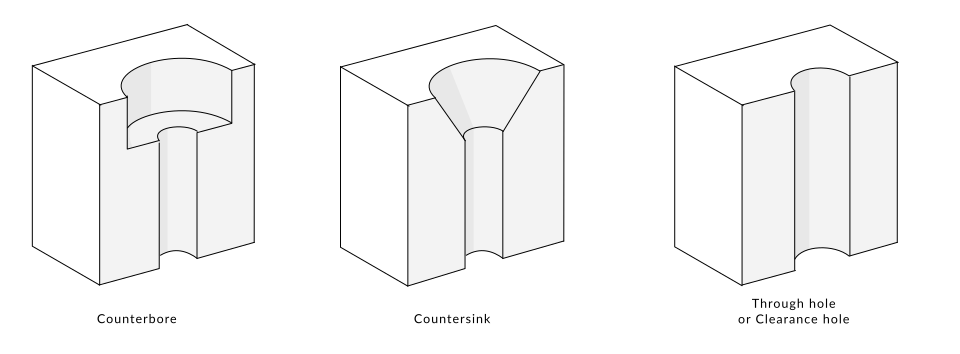

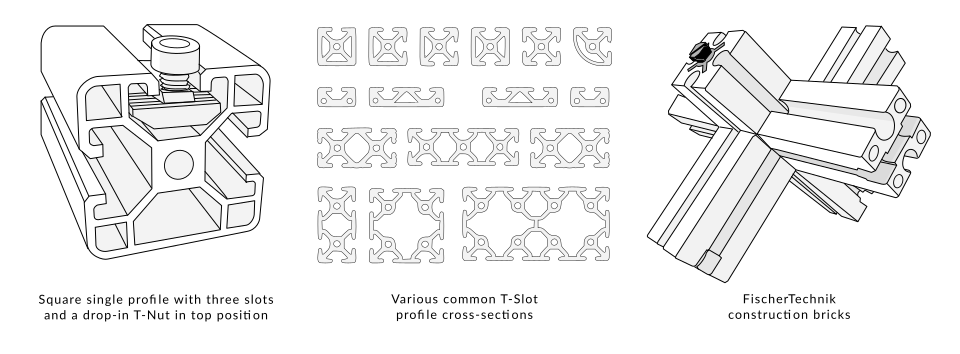

Rack mouting rails (vertical "mounting flanges") may have square unthreaded holes (9.5mm x 9.5mm), round threaded (tapped) holes or unthreaded round holes (clearance holes). Vertically, a standard rack flange has a repeating pattern of either two or three grouped holes. The pattern with a group of three repeating holes is called "universal spacing" and allows finer grained mounting positions, and the pattern with two repeating holes is called "alternative spacing" (or "wide spacing") as it simply omits the "center hole" of the group, resulting in holes being wider apart and enforcing a more fixed module layout within the rack. Some sources imply that this "alternative spacing" is the "older" hole pattern, but in fact these two hole spacing layouts are optional variants already part of the 1960s EIA 310 specs. When vertical mounting rails offer unthreaded (untapped) "clearance holes", EIA specs expect these to be 9/32 inches in diameter (or 0.28125", rounded to 0.281" or 7.1374mm), plus/minus a tolerance of 0.003" (0.0762mm). Metric soft converted specs expected bore holes to be 7.1mm (with 0.1 tolerance) in diameter. Horizontally, hole spacing is 18.312" (or 465.124mm) center to center, also with square holes, toleranced at 0.062". In EIA specs, imperial dimensions are given in decimals with a precision of three digits after the decimal point. Whether or not these decimals result from an underlying dimension of 18 5/16 inch with a tolerance of one fraction (1/16) inch is left to the reader. Whether this tiny uncertainty matters, under given tolerance, as well. One thing to note though is, that holes are not centered horizontally on the rack flange, but are slightly offsetted to rack center. Subtracting horizontal hole-to-hole distance of 465.12mm from the total outer width of 482.6mm gives an outer width of the rack flange of 8.74mm and subtracting the rack opening of 450.85mm from hole-to-hole distance gives 7.135mm inner width of the flange (both to hole center, of course). Regarding the wider outer rim of the flange, note that this is part of the "wiggle room" a rack must offer for front panels (read above in "Rack Flanges"): the rack flange is expected to offer a minimum total outer width ("panel opening") of 19" plus 1/16 inch (or 19.0625" or 484.1875mm) and 19.0315" or 483.4mm suggested elsewhere in EIA specs. A common layout is to have rack flanges 19mm wide (0.75") - with a rack opening of 17.75" this totals to 19.25". Rack holes here are offsetted 12mm (0.47") inwards from each outer side and 7mm (0.276") from the inner flange edge. Between vendors and flange type or material, frontal width ranges from 19mm to 21mm. Some rack types (mostly in the audio field) feature vertical rails made from Extruded Aluminum, where equipment may be mounted at arbitrary positions with a combination of screw and square nuts. Such flanges are often wider, 25mm. Some vendors offer non-standard 4-hole (per height unit) rack rails, where the center hole of a vertical three-hole group is omitted and replaced with two offsetted holes. This allows equipment to be mounted 0.5U vertically apart for better airflow between modules. Most racks however conform to EIA 310 and feature holes at a specified vertical spacing.How tall is 1U?

One height unit (a "rack unit" ("RU"), measured in "U", 1U, 2U, 3U, etc.) is 1.75" (44.45mm) high. This height is based on the mounting hole distance. The original EIA 310 sepcifications used imperial units (inches and punds) and defined the grouped three mounting flange holes (always measured from the hole's center) as 0.625" (5/8 inch, or 15.875mm) apart. The next group of three holes then is spaced a little closer at 0.5" (1/2 inch, or 12.7mm). These patterns start from the top with a first half-step-0.5" (plus some extra space) distance of 0.312" measured from the top of the vertical rail. Distances 0.625" plus 0.625" plus 0.5" give a total of 1.75" height, which is 1U, "one rack unit", sometimes abbreviated as "RU" or height units ("Höheneinheiten", "HE" in German).Metric "soft conversion" discrepancies

These 19" rack dimensions given in inches remained unchanged for many years. Then, during the 1990s, the U.S. government started a number of initiatives to make the country more competitive. As part of the 1988 Omnibus Trade and Competitiveness Act (public law 100-418), the imperial specs were revised in 1992 and the updated document EIA 310-D stated most dimensions in metric values, to better align with international practices and help users in metric countries. But reading the document can be puzzling, as many values are now metric but seem less precise. The explanation is that the actual specs weren't changed, but these metric documents use a process known as "soft metric conversion". In short, this means that imperial values weren't changed or adjusted, for example to align with their closest even metric numbers, with less digits or so. It only means that imperial values were converted to metric values that reflect, more or less, with a certain degree of inaccuracy, the underlying unchanged imperial values, like a rough guideline. These metric values are not fit for engineering application. For example, many values given in these soft converted documents expose a rounding error where values are multiplied, an error only explainable when the reader is aware of the fact that calculations are still done in imperial values, and only the final result is then converted to metric values. So, to sum all this up, 1U is not 1.752" or 44.50mm tall but is still 1.750" or 44.45mm. And hole spacing is not 0.626" or 1.252" but still 0.625" and 1.25".Rack Panels

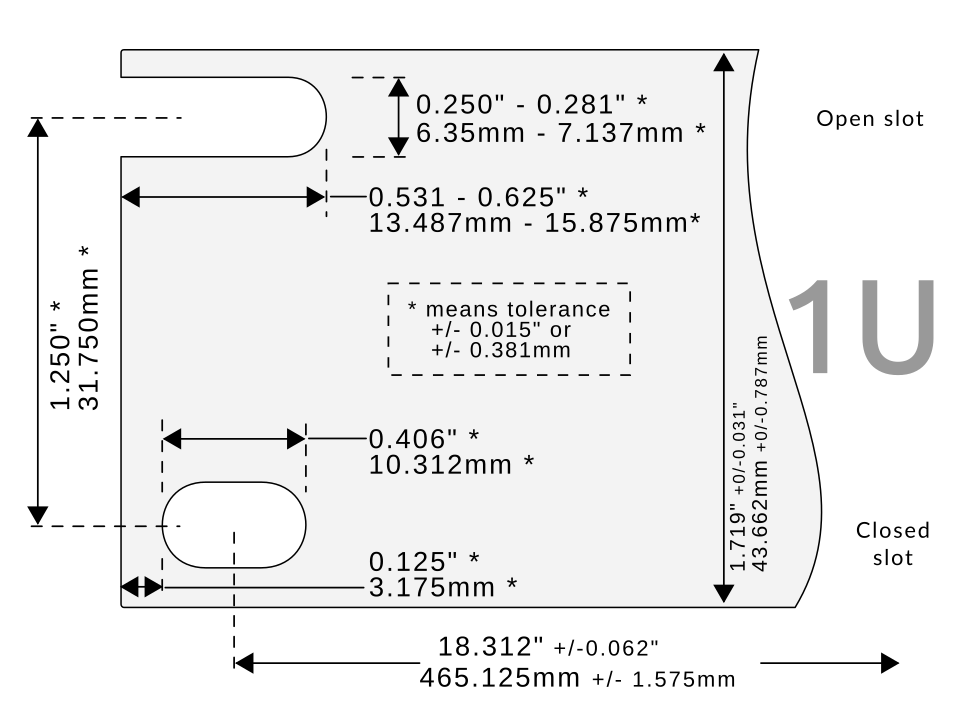

As can be seen in the illustration below, the 19" x 1.75" of a 1U rack slot are the defined maximum outer dimensions for a single rack position, and the maximum size of a 1U module or blank filler panel. While the screw positions inside this 1U envelope are hard defined, the actual outer size of a 1U unit is usually a little smaller than the available maximum and varies slightly between vendors. That said, as per EIA standard, the width of (blank or front) panels is expected to be exactly 19 inches (482.6mm, with a tolerance of 0.4mm), but the height of one panel (or the accumulated height of multiple panels) has to be "one fraction of an inch" or 1/32" or 0.03125 rounded to 0.031" less in height than the maximum available. The actual EIA definition was the "height tolerance" is "plus zero, but minus 0.031". This equals to 0.79375mm, rounded to 0.79mm or 0.8mm, giving modules or blank panels a little "wiggle room". To calculate the height of panels, use this formula: h = (1.750 * n - 0.031) inches = (44.45 * n - 0.79) millimeters, where n was the number of rack units occupied, and h gave the resulting panel height. So a standard conforming 1U panel is 1.71875" tall (rounded to 1.719" in EIA specs and equalling 43.6626mm) - inside the 1U envelope that is 44.45mm (1.750") tall/high. Some sources misinterpret EIA D from 1992 and later revisions and re-define 1U as being 1.752" or 44.50mm tall, but this also stems from a wrong understanding of the "soft conversion" process used in the specifications, as mentioned above. Panel thickness is left to the user to decide upon as needed for the application. Also, with larger, more rack units tall, equipment, the number of slots may be just four or more slots, to increase the load bearing capabilities of a module.Rack Slots

Rack panel holes may be open slots or notches, opening all the way to the side edge of a panel, or closed slots resembling a wide hole. Both of these slot variants are standard as per EIA 310. The inward length of slots, from the side edge of the panel, the horizontal width, open or closed, is 0.531" (1/2" and a fraction, 1/32") at minimum, with open slots allowed to be 0.625" (5/8 inch) wide. Closed slots are expected to have a closed border, to the side edge of the panel, of 0.125" (or 1/8 inch). Both slot types, open and closed, are expected to be a minimum of 0.25" (1/4 inch) wide (tall), meaning the vertical height of the opening, with a maximum opening of 0.281" (1/4" + 1/32"). In metric units this means slots need to be between 13.4874mm and 15.875mm long/wide and 6.35mm to 7.14375mm tall. Closed slots must have a border to the panel side of 3.175mm. The position of the slots is mirrored along the horizontal center axis of a panel and aligns with the rack holes on the mounting flanges. Later metric EIA specs suggested open slots to be (soft converted/rounded) 13.5mm to 15.9mm long/wide and gave a little more leeway for the vertical height, suggesting slots to be 7.1mm tall (equalling 9/32 inches instead of 1/4) and toleranced with +/- 0.3mm, for 6.8mm to 7.4mm.

Rack Screws

While the original EIA specs outline that pretapped mounting holes should be made to accept either a "number 10" (#10) fine thread machine screw (10-32 Class UNC-2B, sometimes 10-32 UNF) or a 12-24 Class UNC-2B as an alternative, the latter number 12 screw is more prevalent in US/imperial datacenters. A 12-24 screw has a slightly larger head and the thread is a little more coarse and this seems to help when mounting larger equipment. Audio equipment on the other hand is often fastened with a 10-32 screw. And to make matters worse, in metric racking environments, it is common to use a M6 machine screw. More recent revisions of EIA 310 prefer metric values and add M5x.8-6H and M6x1-1H screws to the officially defined screw sizes for compliant racks with M5 being the preferred thread size. One thing that this multitide of thread pitches clearly shows is that threads in general may be problematic. And not to mention that threads might get damaged by a wrong screw or repeated change of equipment. Of course, unthreaded "clearance holes" are part of EIA 310, but they require a second tool to hold the counter nut. This is why square holes (square punched "full holes") in racks were introduced. With a square hole an equally square nut can be locked or "latched" in place. A "cage nut" is a square nut wrapped in a small metal sheet (a "cage"), having two or four small spring clips which grip to the square hole. Once installed, the cage nut works like an adapter and can accept either M5, M6, 10-32 or 12-24 screws - whatever fits the installed equipment.- 10-32 Class UNC-2BF

A "number ten" Unified National Coarse, 32 threads per inch (tpi) screw, compliant with the Unified Thread Standard (UTS). The designator "10" is an arbitrary label for the size of the screw, similar to Gauge, with no numerical meaning. The threaded part has a diameter of a little more than 3/16" (0.1900" or 4.8260mm). The V-profile of the thread is the same as for ISO metric screw threads, only the pitch is based on inch values. "2BF" is a tolerance class. - 10-32 UNF

The number "10" Unified National Fine is the same as the UNC number ten screw, except that the thread pitch is smaller and the V-profile is less deep, leading to less travel per turn. Fine pitch screw variants are less common and it should be checked if a rack's threaded holes are really fine pitch. - 12-24 Class UNC-2B

A "number twelve" screw is a little bigger than a #10 and a little more coarse. This screw has 24 turns per inch (tpi). The threaded part has a diameter of a little less than 7/32" (0.2160" or 5.4864mm). - M5x.8-6H

Screws prefixed with "M" are from the ISO metric screw thread series, where the number indicates the screw's nominal outer diameter of its thread in millimeters. An M5 screw has a (major) diameter of 5.00mm. Note that through boreholes for this screw are expected to be a little wider according to EN 20273, 5.5mm. An M5x0.8 screw is the common type with a standard pitch of 0.8mm, or 0.8 threads per millimeter. "6H" is a (common) tolerance class, for V-profile and minor diameter. M5x.8 is the metric equivalent of an UNC screw. - M6x1-1H

A metric screw with a nominal diameter of 6mm and the most common pitch of 1mm (one thread per millimeter). Compared to an UNC 12-24, this M6 screw's threaded part has a diameter of a little more than 7/32" and even 15/64" (0.2362205"). The EN 20273 standard through borehole for a M6 is a little wider, 6.6mm. With a pitch of 1mm, this screw is the "normal", "regular" or "ISO" pitched type, and the metric equivalent to an imperial UNC thread screw. Similar as with "6H", "1H" is a tolerance class.

Rack Positions

When installing equipment, it's necessary to find the right "starting position" so that 1U, 2U etc. rack units line up with the alternating hole pattern on the vertical rack flanges. One method is to look for the vertical holes with the smallest distance between them. These are the two holes only spaced 0.5" (12.7mm) apart. The bottom (or top) line of one 1U unit is right in the middle of these two holes (compare the below illustration). So this "thin bridge" is the line between Us. This 1U separator is sometimes marked on rack flanges with a horizontal printed or marked line (like a punched through small hole). When you start to screw in equipment, align the bottom (or top) of a first module with this line, or make sure that the top/bottom edge of equipment aligns with the middle between these two closely located holes so that mounting notches or mounting holes on front plates line up with vertical rack rail mounting holes. On racks with square rack holes, is is also common to mark the middle hole of a 1U three-hole group with a small side-notch.Rack Depth and Cabinets

While the EIA has defined the front shape of a rack, the depth and what's behind the front rack rail is mostly left to the vendor. And as a rack's depth is the only variable in the equation, manufacturers are making their equipment deeper and deeper in order to max out what can be fit in a given rack slot. That's why 19" rack modules may be short enclosures or very deep. The actual usable depth in a rack is the "mounting depth", while the actual "channel depth" is usually a little deeper, close to the actual overall outer depth/ dimensions of a rack. Larger mounted enclosures, meaning with often added height and usually very deep, are commonly screwed to the front and rear posts, to properly support the heavy weight. When ball-bearing "Rack rails" are used as underpinning in this four-post bolting, the whole enclosure can be pulled out like a drawer for easier access. Such a setup is very common in high density data storage servers or disk arrays, where one enclosure may hold over 300 3.5" hard disk drives and max out the weight capacity of the form factor. So the effective rack mounting depth (in a 4-post rack) is the distance between the front of the front mounting flange to the back side/ rear side of the back mounting flange (or to the backmost unobstructed space within the mounting slot). Common mounting depth were 19" (for a square rack footprint), and 24". And while these smaller mounting depths are still common in traditionally designed rack modules, like measuring apparatuses or audio equipment, the bounding box of rack mount servers and computer systems has grown considerably in depth, to around 29" inches. With 2-post relay racks, the mounting depth usually only describes the "width" (when seen from the side) of the mounting post (the "upright"), but some racks feature more solid uprights, with about twice this depth. Now regarding the total outer envelope of a rack, the frame or cabinet, a complete rack is usually 42U or 48U (height units) tall, with half-height and other form-factors available for space constrained or small office applications. Depth and wide of closed rack cabinets can be much bigger than the actual footprint of the internal mounting rack, to offer room for cabling and attachments in front and on the side of the mounting area. For local IT or audio/IT equipment installations, it is common in back-office environments to have one half or full height rack, self-contained and sometimes sound-proofed, to be operated in lieu of a dedicated server-room.

Mounting flange shapes

Most racks use vertical upright mounting flanges in the shape of an "L", as having a "corner" on the rack, as the mounting flange, is a natural choice. Many flanges on open racks or in rack cabinets where it is possible to access the side of the rack cabinet, have rack holes on the front and on the side of the "L", allowing users to attach more stuff from the side or afix cable binders etc. Another shape found on rack uprights is a square "C" shape, where one "leg" of the "C", the front, is used as the front mounting area and the other sides of this three sided profile provide additional strength. The "C"-shape is related to the shape of the upright posts of a traditional 2-post rack. A third common profile, the "double rack strip", is a four-sided fold in the shape of an "ear" or "question mark" ("?") when seen from the top. It's a "C"-shape with an additional leg on the rear part, forming kind of an "L"-shaped additional mounting front when seen from the side. This additional leg usually also has mounting holes, which can be used to attach, for example, fixed rails (L-brackets) or even rack equipment rotated by 90 degrees in case the rack opening to the side is of standard 19" (on some racks the depth allows 23" or 24" equipment to be installed from the side). One downside, of both, the "C"- and the "question mark"-shape, is that they quite often obsctruct something and prevent Rack rails or similar equipment to be installed easily or at all.IEC Norm 60297 racks

The international (based in Switzerland) organization "International Electrotechnical Commission" (IEC, in French "Commission électrotechnique internationale)") has developed a nested series of norms to describe 19" rack mechanical structures and a system of 19" rack and subrack building blocks down to the PCB level - from rack cabinets (level IV) over rack equipment / module carrier chassis (level III) down to modules (level II) and PCBs (level I). IEC 60297 is largely equivalent or compatible to the standards described in EIA-ECA 310.- IEC 60297 defines the high level 19" rack "grid system", meant as an envelope or root document for the standards series

- IEC 60297-3-100 (read 60297 Part 3-100; formerly IEC 60297-1 and IEC 60297-2) describes the basic dimensions of front panels, subracks, chassis, racks and cabinets (Level IV and level III)

- IEC 60297-3-101 (read 60297 Part 3-101) describes Subracks and associated plug-in units, down to PCB sizes of the "Eurocard" format (level II and level I)

- ... (omitted here, a number of detailing documents, regarding connector alignment, shielding, etc.)

- IEC 60297-3-108 defines standards for "R-type" (ruggedized) subracks and plug-in units, i.e. ruggedized variants of the mechanical structures defined in 60297-3-100, but for heavy weight and large form factor, for large volume applications, e.g. cloud-computing servers, telecom servers

- IEC 60297-3-107 similar to Part 3-108, but for Small form factor and light weight, for large volume applications, e.g. embedded systems, mobile/ubiquitous computing systems

Rack work safety

Although obvious, it might be helpful to point out that racks and rack cabinets are subject to the same laws of physics as any shelf or larger furniture. When heavy equipment is installed in a rack, users should try to place the heaviest equipment closer to the bottom. And while setting a rack up, users should install equipment from the bottom to the top, preventing racks from tipping over. Mobile racks on casters may feature leveling feet that should be extended once a rack has found a temporary final position, so that weight is taken of the casters and the rack establishes a more solid connection with the floor. In case multiple racks are placed side by side ("ganged"), check if baying tabs/ baying brackets can be used to join them together ("standalone vs. gangable setup"). Further, electrical equipment must be properly grounded - in racks potentially requiring running grounding jumpers to a grounding bus. And many electronic devices produce heat in near analog correlation to their power consumption. A 100W system may produce nearly 100W of thermal heat, equalling 341 BTU/h (British thermal unit/ per hour).23-inch rack

The 23" rack is a wider rack format mostly adopted in the field of US telephony exchange infrastructure, sometimes referred to as the "Western Electric standard" due to mostly Western Electric using it. Hole spacing varies and only in some cases matches the 19" norm. A 23" rack is defined by its horizontal hole-to-hole spacing of 22-5/16" (or 22.312", equalling 566.7mm).24-inch rack

The original EIA 320 standard actually defined three rack widths, 19", 24" and 30" with 19 inches being the preferred width. A 24" rack offers a rack opening of 22.750" and can be identified by its hole-to-hole spacing of 23.312 inches (23-5/16" or 592.1 mm).2-Post Rack

also Telco rack (short for "telecommunications rack"). The 2-post rack is the "original rack". 4-post open racks or rack cabinets are essentially 2-post racks with extra supports or a protective enclosure.3-Phase power

as of 2024, the use of 3-Phase power is on the rise in data-centers and server-rooms as it reduces the number of circuits required, optimizes power load balancing and allows a greater flow of power into individual racks.4-Post Rack

Simpler racks are built with a frame of two vertical posts, the rack side rails. With heavier equipment, the front-only screwing mount might exert an excessive force to the front plate and a mounted enclose might bend or break. A 4-Post Rack solves this by offering a second pair of posts on the rear side of the rack enclosure as "Structural support". Bolting equipment to the front and the backside offers sufficient support for even the heaviest of equipment. Apart from additional mounting options, a 4-Post Rack is naturally also the base of most Rack Cabinets, speaking of a "4-Post Rack" with open constructions and an "Enclosed Rack" with side-paneled or closed constructions.500 Series

the "500 series" is a form-factor specification for audio/signal-processing equipment and carrier Subracks, defined by Automated Processes, Inc. (API) during the 1970s. It is sometimes abbreviated as "API 500", stemming from an early EQ cassette sold and manufactured by API, the "API 550". The 500 series format was recently formally standardized and opened by API through their "VPR-Alliance". 500 series shelfes/ cabinets are usually named "housings" or a "lunchbox" (which is an API trade-mark), the latter emphasizing the fact that many users carry their setup of 500 series components (their "custom signal chain") with them on mobile recording situations or to music gigs. Each 500 series module (cassette) is 3U high and 1U wide and connects to a common power and i/o backplane installed on the rear of the rack. Many racks feature on-board PSUs, occupying 0.5 to three of the horizontal rack positions. With a full 19" enclosure offering space for 10 vertically inserted and horizontally organized cassettes (plus a little space left), an onboard PSU usually reduces empty slots to 8. Some 500 series cabinets allow cassettes to be inserted/installed horizontally, 3U high, so that when a "lunch box"-style enclosure is carried or placed vertically (19" perspective: "on the side"), with a handle on one side (then "the top"), the individual cassettes can be accessed and used in their intended upright orientation. API also offers modules for a "200 Series", featuring less tall 1:2 ratioed vertical modules and matching carrier chassis, with 12 slots (and a little) in a 2U 19" rack module.ABC Analysis

Businesses or people handling hardware, installing racks or machinery sooner or later will speak of or hear the term "C-Parts". A "C-Part" is usually a part of low value, like screws in bulk or cage nuts. The term emerged from a business theory created by General Electric manager H. Ford Dickie in 1951. It's a classification system for arbitrary business objects and aims to help identify important goals and assets, differentiating important factors from elements of lesser or neglectable importance. ABC Analysis may be used to categorize business objectives, customers, costs or resources, as for example in inventory management and materials procurement. The labeling here with "A", "B" and "C" establishes as rank and is based on a given asset's importance in reaching set business goals, its value as such or for an intended outcome or its significance in a process.- A-Parts

are usually of high value but ordered or procured in low volumes. - B-Parts

lie in-between in terms of value and handled volume. - C-Parts

mark the other end of the spectrum, are of low value but usually ordered or handled in high volumes.

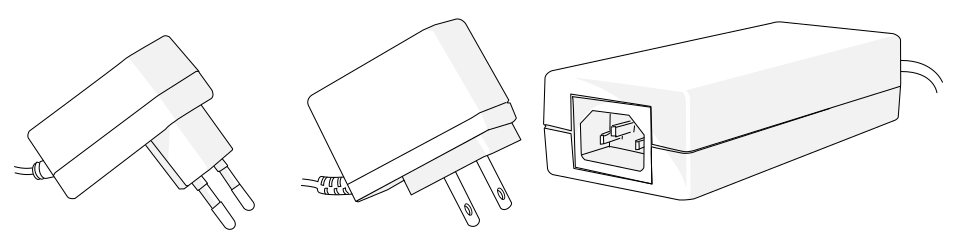

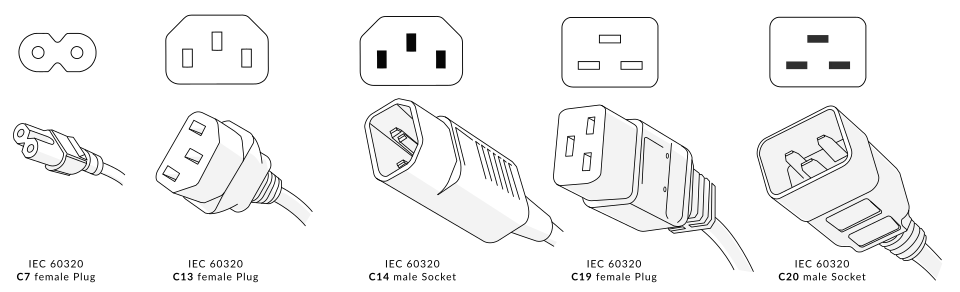

AC adapter

also known as "External Power Supply", "AC/DC adapter", "Wall charger", "Power adapter", "Power brick" or colloquially "Wall wart". An AC Adapter is a small kind of power supply and commonly the consumer or smaller version of a (more industrial, more enterprise-y) Power Supply Unit (PSU). AC adapters usually either come in the form of a corded rectangular box ("power brick") or as a case resembling a larger AC plug ("wall wart").

Air Gapping

From "air gap", also "air wall", is a security measure used in computer networking. The term means isolating a computer, group of computers, or an entire computer network from other, potentially less secured networks ("disconnected network"). In practice, this security measure can be achieved in two ways - by total physical isolation, where all physical and wireless connections are severed, or by logical isolation, using strict firewall rules, encryption, or network segmentation. In data backup, air gaps are also a crucial element, as physically removing - for example DLT tapes from a drive - isolates the written data from any access. While this also prevents the data from being read, such a measure is the most drastic protection against any remote tampering. In backup stores a "virtual air gap" feature represents a middleground, where either software or hardware measures allow objects or written data sets to be set to be "immutable" for a given period ("object lock").Airflow & Cooling

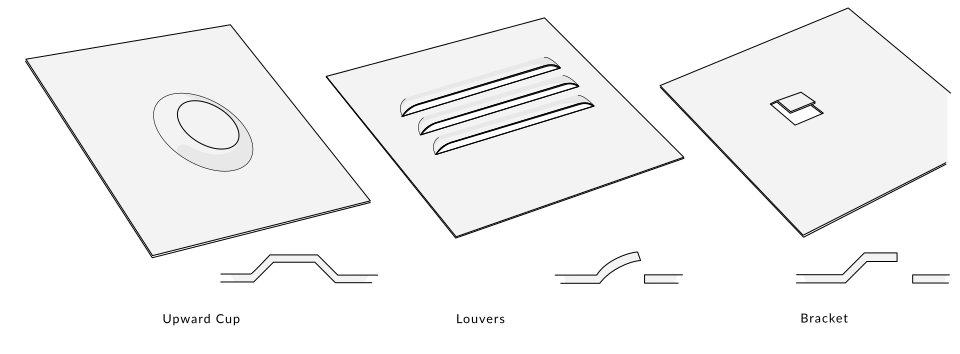

While open racks in early telco installations might have gotten away without a dedicated airflow or cooling concept, in today's high performance world, in data centers and with scientific rack installations, a sophisticated design for proper airflow through and in-between components and an overarching cooling concept is paramount. With high density installations and high thermal power dissipation of individual components, moving heat away from devices and cool air or liquid into components is a challenge. On a per-rack level, cooling is either implemented as passive cololing or active cooling. In passive colling, enclosures are either fully open, or feature specific intake/exhaust openings or have grooves, slotts or perforated doors and panels - allowing air to flow naturally, as warm air tends to go up. The upside of passive cooling is that it is basically maintenance free and produces no noise. The downside is that only a limited amount of air is moved, dissipating only smaller amounts of heat energy. Active cooling concepts, in contrary, use fans, blowers, air conditioning and ducts or even liquid, consume energy and must be maintained. The upside is, that cooling is more controllable and larger amounts of heat energy can be diverted while usually requiring less space and allowing equipment to be denser packed.Many electronic devices, especially computer equipment, produce heat in near analog correlation to their power consumption. A 100W system may produce nearly 100W of thermal heat. Multiplying this Wattage by 3.412 gives 341 BTU/h. "BTU" (British thermal unit, from the imperial and US customary measurement system) is a common unit for the cooling power of air conditioning equipment.

On a data center level, one principle employed in many facilities is the concept of having hot and cold aisles ("Cold Aisle Containment"), meaning, for example, every second corridor in-between server racks is either a hot or a cold aisle, meaning a duct for either hot or cold air. Server racks in such setups are either partly open, without front and back door, or feature perforated doors with a specified percentage of open area (usually over 70%). When air cooled servers or other equipment is installed in such racks, the device pulls in cool air from the front and blows out hot air on the rear. As the rack cages are the only link between the hot and cold aisles, every slot in a rack needs to be either occupied by a device or be closed with a blank filler plate, so that a rack, seen from one side, is a closed wall, separating the hot and cold areas. When unoccupied slots would remain open, the air could circulate through these apertures and the equipment would suck in warm air, rendering the colling concept uselesss. This is only one example of an airflow and cooling concept. Such designs may be based on the per-rack level, executed as a datacenter wide concept or even on a larger scale where a whole datacenteris embedded into a heat dissipation infrastructure, like building a site in cold world regions or where cooling water is found nearby.

As part of a hollistic management of a data center and here equipment cooling, airflow management is one of many disciplines in operating an energy efficient facility. Computer room air conditioning (CRAC) units are precision AC systems built for data centers but based on the same compressor plus refrigereant layout that domestic AC systems are built on. Computer room air handlers (CRAH) have no compressor and use chilled water instead of a refrigerant. Further, it is important to manage and control how air is flowing in the datacenter and where it is led, in what amount and at which temperature. Over-provisioning air flow to the cold aisle can result in a cooling air bypass, meaning too much chilled air is made available. Under-provisioning cold air flow will lead to equipment running hot, building up hot spots in racks or datacenter areas, elevated fan speeds on equipment and potentially hot air recirculation. Specific structural elements (air skirts, air dams, curtains and even blank filler panels) can be used to guide and direct air towards equipment. Sensors can be used to measure intake temperature or detect hot spots. And an active monitoring in sophisticated systems may be able to regulate airflow and temperatures based on the current workload of running systems and their resulting heat dissipation on a per rack, per aisle or datacenter wide level.

One of the most effective technologies to cool IT equipment is liquid cooling. Systems may be either fully immersed into a cooling medium (Liquid immersion cooling) or ducts and pipes may direct a coolant (often distilled water) to heat exchanger blocks mounted on specific hot areas, like GPUs, CPUs, etc. (Water cooling). Once the liquid medium has absorbed the heat of a system, it it pumped or directed to a heat exchanger, like a radiator, to dissipate the accumulated heat and then recirculated back. Systems may be either active (using pumps) or passive (relying on hydraulics to circulate the coolant. In comparison with cold air cooling, using a liquid medium bears obvious challenges in operation, as electric equipment and usually ductible liquids are natural opponents. But while the elevated complexity of liquid cooling or the potential of damages or leaks are downsides, the high efficiency of the technology is the reason for more and more datacenters switching to this technology - either in smaller specific areas or larger parts of the IT stack.

Airflow Violation

in data centers or computer rack installations, there are commonly guidelines and rules in effect about how heat is dissipated via airflow, per rack, per cabinet, per aisle etc. When equipment is installed in a way that breaks these rules, the overall airflow concept is degraded. This can happen when blanking panels are omitted and hot and cold air can mix, creating turbulence, or when rack-mounted systems are installed the wrong way, with outward-blowing fans facing the air intake direction, for example. This can be labeled as an "airflow violation".Aluminum

or "Aluminium" in British English and many European languages, is a chemical element denominated by "Al" from the group of metals, often abbreviated as "alu", a light metal with a visual resemblance to silver. As aluminum is not containing iron, it is grouped in metallurgy as a non-ferrous metal. In comparison with precious metals like gold or silver, aluminum is a base metal and is quick to react on clean surfaces with air and water to build an aluminumoxide layer. This means that aluminum has to be properly primed before a number of coatings would build a lasting bond with the metal's surface. Aluminum is an abundant material and thus popular in construction, computer cases, electronic boxes or IT racks. As aluminum is more expensive than steel or iron, aluminum is usually used only where wheight is a defining factor, for example in aerospace applications. In addition, the cost factor is influenced by the fact that aluminum is softer than steel and requires thicker or more solidly designed structures to achieve similar rigidity. While it is usual to refer to all these embodiments as "aluminum", the actually used metal is mostly an alloy where aluminum is the primary element. Common aluminum alloys are aluminium–magnesium alloys (AlMg), like "AlMg1", "AlMg3", or alloys with a small amount of manganese ("AlMgMn", like "AlMg4,5Mn0,7"), aluminium–magnesium–copper alloys ("AlMgCu") or aluminium–magnesium–silicon alloys ("AlMgSi"). Apart from aluminum alloy sheet metal blanks, formed and treated in a number of ways, "aluminum" is often extruded into profiles, for example the popular T-Slot alu beams.Aluminum priming

Aluminum has many desirable properties but also the undesirable property of building an aluminum oxide layer on the very surface, by itself and quite quickly. And while this natural process is good in protecting the aluminum against environmental influences, it is also the reason why aluminum is relatively difficult to paint or coat. Enamel and acrylic varnishes will simply not adhere ("stick") to untreated aluminum and paint is destined to come off in places. Mechanical aluminum preprocessing, like sanding or washing, even just before painting, won't perfectly remove the oxidized layer. Thus, in painting or coating aluminum, a specialized primer solution has to be applied, sprayed or painted, in order to allow the varnish to build a firm bond with the metal.Angled Rack Stand

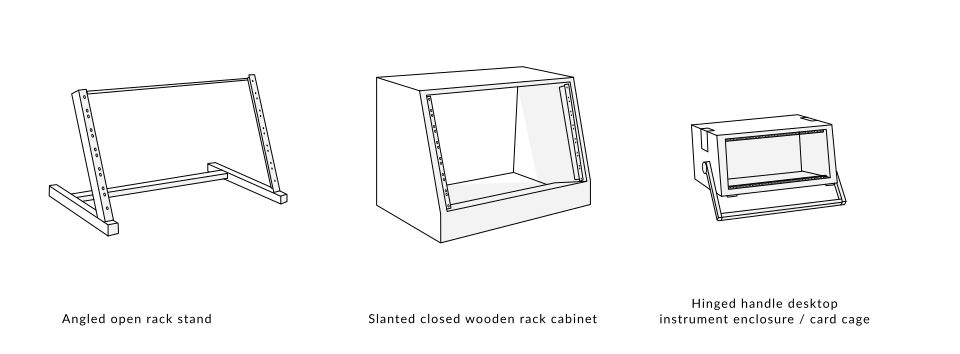

Especially in audio and music production, the use of smaller, sub-rack-type angled cabinets is common, a type of rack that features an angled front, inclined towards the user. These racks are mostly used to rack only a few devices, around 3U to 6U. Designs of angled racks are either simple metal frame layouts in the form of open racks, or closed small cabinet styles, often wooden racks, where the upper part is slightly slanted. Open rack types and cabinets usually feature an inclination of around 20-40 degrees backwards (negative, away from the user) so that the front-plate of installed equipment is easily reachable and readable by the user. One common problem with the slanted design is that the bottom rack slot is not able to fit a full-size (deeper) rack device, as the slant means the depth of the slot is limited by the bottom side or base of the rack stand / cabinet. Some designs thus feature a small elevation of the bottom-most slot to add more depth to this lowest rack position. Small card cage-style enclosures featuring a hinged handle are usually called desktop (instrument) enclosures. Compare Desktop Rack.

Anodizing

Anodizing is a surface finishing process for metals. Anodizing is one form of surface passivation and part of a number of processes of intended anodic surface oxidation. Different techniques of surface anodization exist, with an electrolytic passivation process sometimes known as "Eloxadizing" (a German word creation) being the most popular. The Eloxal anodizing treatment actually transforms the uppermost surface of an object by growing an oxide layer, usually to the same amount "into" the surface as it "grows" to the outside. This actual transformation of the surface is different from galvanic processes where a different material (usually zinc) is laid (applied) onto the metal surface. Anodizing is a measure to prevent rusting (corrosion). It is possible (and popular) to create colored anodized aluminium.ATA road case rack

The abbreviation "ATA" is short for "Air Transport Association of America" (ATA) the older name of today's "Airlines for America" (A4A), a central organisation for lobbying and standards in the aviation industry. One standard brought forth by ATA was the "Specification 300" dating back to 1960, describing a case that is "Reusable for a minimum of 100 round-trips usually fabricated out of plastic and / or metal" with "(a)ll hardware, including fasteners used to secure a lid closed, shall be recessed, flush or guarded so that no protrusions could cause damage to the container or to other goods shipped in the same conveyance" (Specification 300, 2008, pages 31 and 22). For touring bands and troupes, such cases became the go-to boxing for equipment, and also for readily installed 19" rack based equipment. This is where the term "flight case" came from, or from being on tour, "road case". The common appearance in black wood or plastic with silver aluminum or steel corners became synonymous for a "flight case", even when it doesn't adhere to original ATA specs. For easier handling, ATA compliant rack cases are usually not 42U / full-height tall, but shorter, of around 21U and on caster wheels. Inside, flight case racks are often insulated and shock-proofed, via damping material or spring mechanisms. Cabling from one of those racks to another or to amplifier, speaker or light equipment is usually done via Harting connectors and thick "cable snakes" ("cable assemblies").Automatic Transfer Switch

sometimes "Auto Transfer Switch", is a feature of Power Distribution Units (PDU) to offer power redundancy on the PDU level. Having a PDU connected to multiple power sources, "ATS" is an in-built mechanism of the Unit to switch from one power source to the other in case of failure of one.AWG

short for "American Wire Gauge", sometimes "Brown & Sharpe Wire Gauge", is a coding system for the diameters of round, solid, nonferrous, electrically conducting wire, usually made of copper or aluminum. AWG is predominantly used in North America, coming from a standard established at U.S. corporation Brown & Sharpe in 1857. It consists of logarithmic stepped increasing gauge numbers that denote decreasing wire diameters. As a conductor's surface is directly linked to its current-carrying capacity, AWG numbers and the cross-sectional area of each gauge is an important factor in wire selection for electrical installations. Note that AWG is for solid conductors. With stranded wires having small gaps between each individual strand, achieving a similar cross-sctional area requires a little more room thus a stranded wire always has a slightly larger overall diameter than a solid wire with the same AWG. Refer to "Gauge" for an AWG conversion table.Baying brackets

Rack frames and enclosures usually offer a number of different options to install, bolt down or afix a system to a wall, the floor or movable bases - via a number of optional mounting points. Many mounting points are slotted apertures, allowing screws to be put through, often in a bayonet mount -style fashion. Some racks feature "baying brackets", "baying tabs" or other systems ("joining kit") to connect racks side-by-side or over-another. Joining multiple racks improves overall stability, preventing racks from tipping over or move. Especially in A/V and mobile/roadshow uses, it is common to have smaller racks, half-height 21U or similar, for practical reasons, that are then stacked two racks high and bolted together for temporary installations.Bend Radius

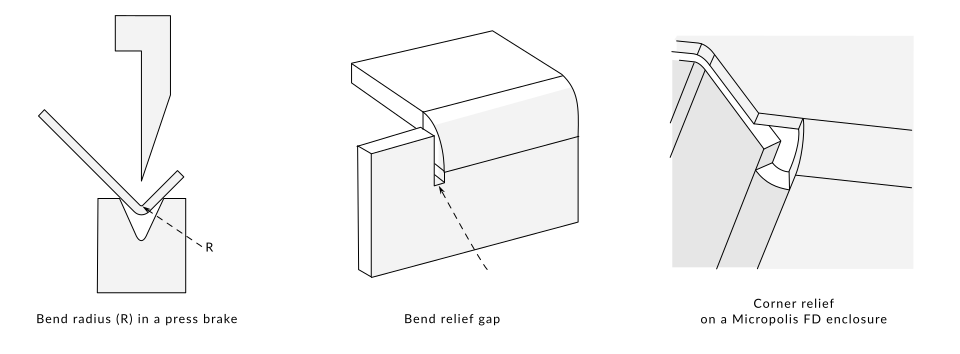

is a term from the field of sheet metal forming. Similar to folding paper, sheet metal can be folded or "bend" to form flanges into angles of 90 degrees or arbitrary acute or obtuse angles. The bent area, a linear ridge, has an inner and an outer radius - depending on which side of the resulting flange one measures. And while designers tend to think that it is possible to form, for example, a box from sheet metal without any bending radii, the reality is that sheet metal bends always form a rounded corner, not a perfectly sharp edge. When a flat sheet of metal is formed, for example in a press brake, the punch is only able to press the metal into the die to a certain degree, otherwise the metal may crack, either already during manufacturing or later, down the line, when some form of stress is applied. That's why a minimum bend radius is used for all bends during manufacturing. The actual bending radius depends on the thickness and the malleability of the formed material. For steel, the rule of thumb is to use bend radii equal to the material thickness, meaning 1.5mm steel asks designers to incorporate inner bend radii of 1.5mm into their designs. Aluminum is softer and common bend radii for this material are either a factor of 0.8 or even down to half the material's sheet thickness. Similar is true for copper or brass.Bend Relief

is a term from the field of sheet metal forming. When sheet metal is bent, for example in a press brake, the area where the metal surface transitions from a flat area into the bend, or in-between two bends, depending on material properties, the material may tear at the bend's side. In order to prevent tearing, the general rule in sheet metal bending is to apply a "bend relief", "relief groove", "relief notch" or "relief gap", a small area around a bent corner that is widened to allow the material to distribute the stress of the bend more evenly. Bend reliefs may be "straight" rectangular notches with right-angled corners, "rounded" slots ("obround") or circular ("round") cutouts covering the high stress area. The width of a relief is usually at least half the thickness of the used sheet material and extend a fraction behind the bend. After fabrication, bend reliefs also contribute to the longevity of a workpiece, as proper reliefs help prevent fracture propagation, improve durability under vibration and surface coatings are spread more evenly as fabrication without bend reliefs may produce burrs or sharp points. On metal enclosures, in corners where three flat surfaces meet, the bend recess or corner relief can often be noticed as a small hole or eye.

Blanking Panel

Many rack mounts or cabinets offer more space than is occupied by front-facing equipment. In order to tidy up the appearance of a rack, optimize Airflow or secure critical cabling, an unspecific simple piece of sheet metal or extruded aluminum can be bolted into free units of the front-, rear-, or both sides of a rack. Blanking Panels (also "blanking plate" or "Blank Filler Plate") are sometimes customized with DIY modifications (drilled holes, sawn openings, etc.) to serve specific mounting needs of non-standard sized devices. Some blank panels are metal and screwed in place, while others are plastic or other flexible material, that is attached in many height units at once, like a rolling shutter on a window, and fixed to the rack rails with a simple clip-on system. Some blank rack panels may play an integral part in the structural struength of a rack system, while with other racks, using a blank filler panel is optional, a matter of preference, visual style or a needed element in an airflow concept.Brush Panel

Blanking plates come in many forms, with ventilation openings, with cable ducts, cable management hooks etc. A "brush panel" has a large opening with an inserted horizontal brush curtain, so that cables can be easily run through it and the brush bristles acting as a simple seal around the cabling, helping to control air flow inside a cabinet.BMC

abbreviation for "Baseboard Management Controller" (sometimes "Board Management Controller") is a small dedicated computer-system (a microcontroller) embedded into the mainboard (baseboard) of systems that are usually operated remotely, like racked server systems in datacenters or NAS systems in off-site locations. A BMC is the central hub for sensor data, system state, power cycling and other means to supervise and control the host system. A BMC can be part of the IPMI control stack and may communicate over IPMI protocols. Often BMC networking is separate from host system networking, adding an additional layer of security by using a dedicated communication network or serial connection. The software (client) counterpart of the BMC is the "BMC Management Utility" (BMU), usually a command-line tool to communicate with a remote BMC. Some BMCs offer a web interface.What are C-Parts?

The term C-Parts emerged as part of a structured approach in business theory called "ABC Analysis". In practice, ABC analysis found application in material management and supply chains. C-Parts according to the ABC classification are parts of low value but parts that are usually handled, ordered or procured in high volume, usually in bulk, are difficult to order and manage and often impossible to substitute - despite their low value. Small things like washers, nuts, screws, bolts or cage nuts are usually labelled as "C-Parts". In electronics, simple semiconductors are dreaded C-Parts and may bring whole product lines to a halt.What is a cable?

A cable is a collection of wires. While the terms cable and wire are often used interchangeably, there's actually a difference. The wire is the conductive metal part, often copper, aluminum or an alloy, which may be made of a solid extruded piece of metal or multiple strands. A wire doesn't necessarily have to be protected on the outside by a non-conductive material. However, a cable is a collection of wires where each wire is protected (insulated) against contact with the other wires in this cable by some form of non-conductive material, individual thermoplastic sheaths around each wire or by embedding all individual wires in some common insulator material. The collection of wires inside a cable is usually wrapped together by some form of outer cover, made from the same or a different insulator material as used for the internal wires. It is common to have wires and/or cables being wrapped by silicone, rubber, textile meshes, thermoplastics, vinyl, rubber, polyurethane or heat-shrink plastic. With many cables, complex cabling or in combination with movement, cable and wiring systems may need some form of "Cable management".Cable Arm

Some rack cabinets or rack mount equipment features specially designed "cable arms" as part of cable management. When installed equipment is, for example, placed on rack rails and is later pulled out for maintenance, the multitude of cables routed to a server or storage enclosure might get in the way, get damaged or get pulled out. In order to prevent cables getting stuck or in the way, all cables during setup of a system are placed on specific articulated cable arms, a system of links and joints, bolted to the enclosure or the rack cabinet. When a system is pulled out, the cable arms swings out accordingly, supports the cable and manages them in a predefined way, so a system may continue running uninterrupted or the cabling loom of the installation remains intact.Cable Classes

Computer networking Patch Cables are divided into several classes, where each class defines the amount of shielding employed and the maximum frequency rating. Electrical ("copper") cables are categorized as:- Class A: Up to 100 kHz using Category 1 cable and connectors

- Class B: Up to 1 MHz using Category 2 cable and connectors

- Class C: Up to 16 MHz using Category 3 cable and connectors

- Class D: Up to 100 MHz using Category 5e cable and connectors

- Class E: Up to 250 MHz using Category 6 cable and connectors

- Class EA: Up to 500 MHz using Category 6A cable and connectors (Amendments 1 and 2 to ISO/IEC 11801, 2nd Ed.)

- Class F: Up to 600 MHz using Category 7 cable and connectors

- Class FA: Up to 1000 MHz using Category 7A cable and connectors (Amendments 1 and 2 to ISO/IEC 11801, 2nd Ed.)

- Class BCT-B: Up to 1000 MHz using with coaxial cabling for BCT applications. (ISO/IEC 11801-1, Edition 1.0 2017-11)

- Class I: Up to 2000 MHz using Category 8.1 cable and connectors (ISO/IEC 11801-1, Edition 1.0 2017-11)

- Class II: Up to 2000 MHz using Category 8.2 cable and connectors (ISO/IEC 11801-1, Edition 1.0 2017-11)

- OM1: Multimode, 62.5 μm core; minimum modal bandwidth of 200 MHz·km at 850 nm (retired)

- OM2: Multimode, 50 μm core; minimum modal bandwidth of 500 MHz·km at 850 nm (retired)

- OM3: Multimode, 50 μm core; minimum modal bandwidth of 2000 MHz·km at 850 nm

- OM4: Multimode, 50 μm core; minimum modal bandwidth of 4700 MHz·km at 850 nm

- OM5: Multimode, 50 μm core; minimum modal bandwidth of 4700 MHz·km at 850 nm and 2470 MHz·km at 953 nm

- OS1: Single-mode, maximum attenuation 1 dB/km at 1310 and 1550 nm (retired)

- OS1a: Single-mode, maximum attenuation 1 dB/km at 1310, 1383, and 1550 nm

- OS2: Single-mode, maximum attenuation 0.4 dB/km at 1310, 1383, and 1550 nm

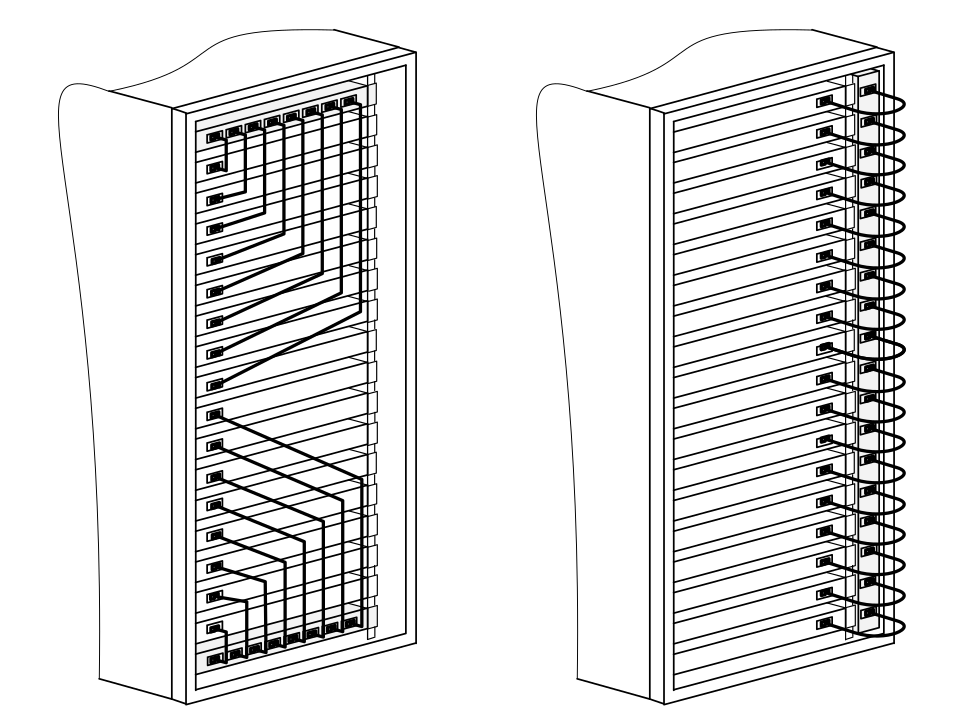

What is a Cable harness?

Often when cables are bound or assembled together as part of a thicker bundle of cables, some sort of "Cable management" is used to improve maintainability, operational safety and reduce faults, by preventing wiring failures or people or equipment getting entangled in cables. Some simple form of cable management is pulling individual cables through cable ducts, but during manufacturing, when the same wiring setup is repeated many times, this may lead to wiring faults or unnecessary stress on individual cables. Thus, in the early 20th century, it became popular to bundle cables in ad-hoc bound or pre-assembled cable harnesses. Sometimes different terms are used to describe different types of Cable harnesses ("wire harness", "wiring harness", "cable assembly", "wiring assembly" or "wiring loom").A "wire harness" is usually the most simple form of a cable assembly. Here, a bundle of usually single core wires (so its probably better to speak of a "wire harness") is assembled into one bundle of wires, each isolated against each other but bundled. Over the years different techniques of cable lacing were used, with rope, with tape, with cable ties, knitting in elaborate patterns. A wire harness usually has each single wire visible.

More elaborate are "Cable assemblies", where a number of cables are combined into one (thicker) sleeve. In contrary to a wire harness, a Cable assembly usually is a bundle of cables, meaning the individual "wires" are actually multicore cables. A cable assembly has all included cables protected by a single outer protective sleeve, giving the appearance of one thicker cable.

A "Cable loom" (sometimes less exact "wiring loom", or "electrical loom") in turn is a bundle of multiple Cable assemblies, wire and combinations thereof into one complex system. Many cable looms have the appearance of wiring harnesses, but each component is a multicore cable or wire connection.

Wire harnesses and Cable looms often are pre-fabricated on dedicated pinboards, where a defined routing layout is used to route wires and cables into a specific pattern, giving the resulting assembly a specific shape, where individual wires or cables may have different length, following defined paths or breaking out from the harness/loom at specified points. After a build, technicians can tests such pre-assembled harnesses/looms by connecting the assembly to test circuits. During installation of such assemblies, having a tailored bundle decreases installation time, prevents mistakes and helps with the standardization of work processes.

Cable Management

Cable management as a general practice is the process or guideline of laying, routing and pulling cables in a tidy and organized way. With moving systems, where cabling is applied outside the moving structure, like with robots or when connected modules move relatively to each other, carefully controlling cable flex improves security and maximizes cable life. Thus, cable carriers for cables and hoses are commonly used on industrial robots or in rack equipment to optimize cable management. From a more general perspective, cable management is an important aspect of mechanical and electrical engineering, inside machines and housings and cabinets. One important technique is to gather a number of cables in "Cable ducts" or assemble multiple cables as part of a "Cable Harness".Cable Raceway

also "cable rack". A light steel frame structure, usually located over racks or rack cabinets to lead cables to individual racks, commonly suspended on threaded rods from the ceiling. In data centers, usually network cabling is done separately from power cabling, so that high power connections don't induce a charge into network cables. It is common to place low power cables, like networking cables, in overhead cable ducts, cable raceways, and have mains power be connected from under the elevated floor.Cabling Standard

There are a number of standards regarding data center cabling, giving advice and setting best-practices for (structured) rack cabling, rack to rack cabling, row cabling, and data-center wide / backbone or facility cabling.- ISO/IEC 24764

more specifically "ISO/IEC 24764:2010(E)" specified generic cabling systems for data centers, supporting a wide range of communications services. It covered balanced cabling and optical fibre cabling. It was based upon and referenced the requirements of ISO/IEC 11801 and contained additional requirements that are appropriate to data centres in which the maximum distance over which communications services are distributed does not exceed 2000 meters. This now replaced standard has been revised to form "ISO/IEC 11801-5:2017", incorporating corrigenda and amendments of "ISO/IEC 24764:2010/Amd 1:2014". - ANSI/TIA-942

Telecommunications Industry Association (TIA) ANSI/TIA-942-B (in revision B), officially the "Telecommunications Infrastructure Standard for Data Centers" is an "American National Standard" (ANS) setting minimum requirements for data center infrastructure. It certifies that design documents of compliant equipment have been reviewed for conformity to the design criteria, aligned with a certain "rating level". For facilities, that design documents have been physically onsite inspected and been verified and practices like modularity have been implemented according to the standard an a respective "rating level". These "rating levels" refer to the standard's four rating levels: "Rated-1: Basic Site Infrastructure2, "Rated-2: Redundant Capacity Component Site Infrastructure", "Rated-3: Concurrently Maintainable Site Infrastructure" and "Rated-4: Fault Tolerant Site Infrastructure", the highest level and most redundant type of rating. As of 2024, the standard is again under revision and about to be released as "ANSI/TIA-942-C" (revision C). - ANSI/BICSI 002-2014

is an "American National Standard" (ANS) for Data Center Design and Implementation Best Practices. It is usually regarded as complementing the ANSI/TIA standards, as BICSI publications tend to be more detail-oriented than TIA standards. BICSI as such provides detailed guidelines for the layout of mechanical, electrical or thermal systems of a data center, and taking related topics like security considerations into account.

Cage Nut

A "cage nut" ("captive nut" or "clip nut") is a square nut wrapped in a small metal sheet (a "cage"), having two or four small spring clips which grip to square holes of vertical rack rails. As defined in various standards, 19" racks may feature threaded or unthreaded holes, but threaded holes may get damaged and unthreaded holes require a nut and a second tool to hold the nut while fastening the screw. For quick installation or tool-less mounting, square rack holes were introduced and with these a "cage nut" is needed to mount equipment. Once installed, the cage nut works like an adapter and can accept either M6, 10-32 or 12-24 screws - whatever fits the installed equipment. The cage of such a nut sits a little loose inside the square rack hole but locks tight once the equipment is screwed in. Note that such cage nuts, due to how deep the little metal collar is, need to fit the thickness of the rack strip they are clipped into. Rack strips may be thin 1mm metal or thick heavy duty material of 2mm or more.The thing with cage nuts is that they are manually quite difficult to insert into the full square holes of a rack strip. The little spring collar may be hard to compress, can snap back and injure the rack worker. Or cage nuts are quick to pop out while inserting them, fall down and make all sorts of headaches. That's why many companies have tried to improve the situation. Some rack equipment, like heavy duty server rails, come with built-in rack hole fasteners that are easy ("tool less") to insert and lock. And for installations based on loose cage nuts, a number of cage nut tools and helpers are offered. Some have tried to improve the design of cage nuts themselves. Former times Micropolis neighboring company Chatsworth Products offers the patented "clik-nut", where an elongated lever arm helps to compress the cage nut cage. Others have reversed the nut into a threaded rod that is inserted from the back of the rail and makes the rod stick out to the front, offering guidance during installation and subsequently easy fastening with a thumb-size nut from the front of installed equipment. These ideas and innovations come in a number of shapes and forms and it's up to the user to decide which one is best.

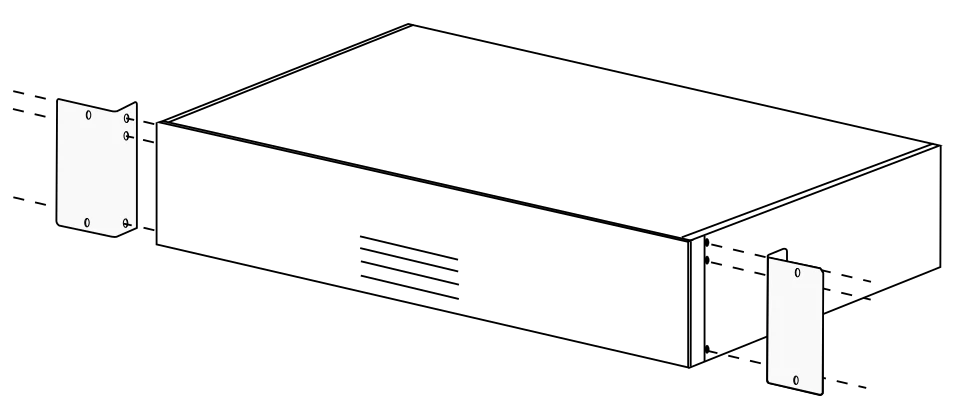

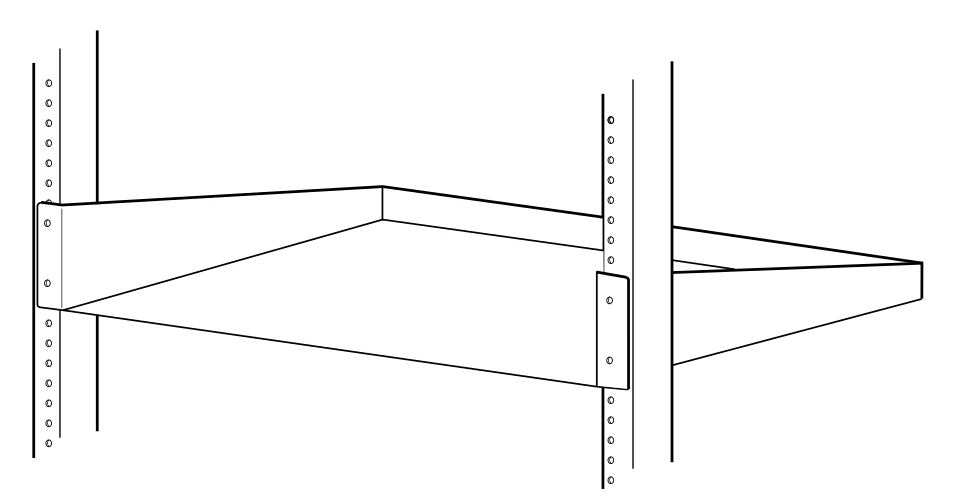

Cantilever Rack or Shelf

Cantilever is a synonym for a simple beam or statically loadable arm holding a weight. In logistics and storage, Cantilever Racks are open racks with shelving levels made up of horizontal steel beams, usually used to store long goods, like carpet coils, wood packages, sheet metal. In a datacenter context, a cantilever rack or shelf is a type of Rack Shelf with a slanted support structure or side beam, and as any rack shelf can be used to store arbitrary smaller hardware and/or devices. Sometimes an interlock system (grooves or cut-outs on the shelf bottom) is offered to attach smaller sub-assemblies to hold (consumer) devices, for example large numbers of mobile phones, side by side in high density, for Ci/CD ("continuous integration and continuous delivery") applications, where apps or software is tested on many hardware platforms to guarantee compatibility, etc. Cantilever Racks are sometimes customized with DIY modifications to serve specific support needs.Casters

Especially smaller racks or subracks are often put on casters. Casters are either one way or rotatable, can be heavy duty or limited in weight capacity. For heavy duty equipment, casters are often complemented with rectractable leveling feet, short threaded rods, that can be extended further than the casters' height, lifting the rack from the casters / ground, making it immobile but adding much to a firm stand of equipment, even allowing the user to compensate for smaller floor uneavenness.Certification and Compliance Marks

Electric and electronic devices usually feature one or many certification marks, stylized icons that are awarded to products after testing and proving their conformity to certain standards or to represent guarantees given by the manufacturer. Such marks are specific to their respective regions or standards and the intent is to help consumers make informed purchasing decisions and/or ensure product safety. Worldwide, various seals indicate compliance with local regulations or requirements. The "EAC" mark is the "Eurasian Conformity" mark and is similar to the "CE mark", but specifically applies to the Eurasian Economic Union. The "FCC" label, issued by the "Federal Communications Commission" in the U.S., certifies that a product operates within specified limits for electromagnetic emission and interference. The EU's "RoHs" guidelines restrict hazardous substances used in electronics and many PCBs show the accompanying icon. The EU's "Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)" is a similar regulation and governs chemicals. Some of these marks are described in more detail below:CE Mark (Conformité Européenne)

The "CE" mark indicates that a product complies with essential health, safety, and/or environmental protection requirements within the European Union (EU) and the European Economic Area (EEA). Depending on product category, and in case an EU specification for this category exists, a product requires the affixing of CE marking. The manufacturer bears sole responsibility for declaring conformity with such requirements. Products may be either self-assessed by the manufacturer or by an independent notified body. Once a product bears the "CE" mark, a national authority may at any time request information and supporting documentation concerning the product's certification.UKCA Mark (UK Conformity Assessed)

When the United Kingdom exited the European Union ("Brexit"), national authorities decided to introduce a local successor for the EU's "CE" mark. Similarly to the "CE" mark, the (officially) "UK marking" or "UKCA marking", short for "UK Conformity Assessed", demonstrates compliance with regulations in effect in Great Britain (England, Scotland and Wales) for certain goods placed on this market. When the UK marking forked from EU's "CE" in February 2020, regulations were largely consistent, but local legislation has diverged over time. Due to specific situations in Northern Ireland in relation to the separation from the EU, this region typically employs the "CE" mark. However, only certain categories require certification through a UK body, after which they bear the "UK NI" marking.GS Mark (Geprüfte Sicherheit)

The German "GS" mark, sometimes called a "Seal" (German "Siegel"), comprised of two stylized letters "GS", short for "Geprüfte Sicherheit" ("Tested Safety"), indicates that a product meets safety requirements set by the German Product Safety Act ("Produktsicherheitsgesetz", or "ProdSG" abbreviated). According to this legislation, a manufacturer is only allowed to introduce a product on the German market after making sure that it doesn't impose a safety or health risk for a consumer. The mark can be found on many ready-to-use consumer products, like electrical equipment, furniture, toys, home appliances or textiles. The "GS" mark is granted only after an independent and listed body has tested the product to ensure positive compliance with applicable regulations. Additionally, the product undergoes regular re-audits throughout its life-cycle. Some but not all regulations overlap with EU regulations. After certification, the manufacturer has proven compliance as required by law and may affix the optional "GS" mark on a product, without the actual need to do so. The "GS" mark is the sole European product safety certification that is regulated by national legislation. While many consumers view it as a seal of quality, actual quality measures like longevity or user-friendliness aren't evaluated as part of certification.UL Mark (Underwriters Laboratories)

The UL mark is a family of certification seals issued by the private "UL enterprise", an organization comprised of several specialized safety science and testing laboratories. UL marks prove that a product or component complies with US laws and meets defined safety requirements and quality standards. Manufacturers in the United States are not legally required to send goods through UL certification but having this mark on a product provides consumer confidence on the US market, similar to foreign quality and/or safety seals. The family of UL marks consists of two (three) main marks:- "UL Listed" is for an entire (stand-alone) product, which may be an assembly of components. It means that UL has tested representative samples of this product and has determined that the product meets specific, defined requirements which are applicable for the respective category of products. These requirements are based on UL's published and nationally recognized standards for safety and/or health.

- "UL Recognized", "UL Component Recognition", the "Recognized Component Mark" or the stylized reversed "RU" means that UL has evaluated an individual component or material that is intended for use in a larger product or system. Such components are intended to be part of an UL certified end product, but alone aren't fit to bear the full UL Mark themselves. The "RU" mark is not intended to be end-user facing and can often be found on internal components or PCBs.

- "UL Certified" is an extension of "UL Listed" and means that the manufacturer of an "UL Listed" product agrees to a specific list of guidelines and continued monitoring by UL. Similar to the German "GS" mark, a manufacturer will then have products regularly re-evaluated, and UL representatives may even perform site visits to ensure that the manufacturer remains in compliance with the established regulatory standards.

VDE

The VDE certification mark indicates that an electrical or electronic product adheres to a number of safety and quality standards. The private German union "VDE Verband der Elektrotechnik Elektronik Informationstechnik e.V.", formerly called "Verband Deutscher Elektrotechniker" (VDE) operates a number of groups active in standardization, testing and education. The "VDE" safety and quality seal is awarded by the "VDE Institut" and guarantees a product's conformance with electrical protection, safety and quality requirements, as defined by VDE's own specifications and standards or with regulatory requirements in Germany, the EU or worldwide. Particularly in Germany, customers have come to associate the VDE seal on devices with reliability and safety.Co-Location Cabinet

depending on style often written as "CoLocation Cabinet" in CamelCase, is a type of 19" (computer) rack that features multiple, often three, front doors, offering three isolated racking compartments, with heightened security features, locks and an overall sturdy design, so that data centers offering access to equipment by their tenants can allow access to the data-center floor and a customer's rack without exposing other tenants' equipment to unauthorized access.Cluster

while Cluster is a broad term in computer science describing a number of interconnected systems, a cluster in data storage represents a group of storage devices connected together to form a unified storage in order to provide scalability, enhanced data availability and distribution, resilience, and higher performance. Storage clusters are commonly used in distributed file systems and cloud storage where the amount of data is constantly growing and clients handle large datasets.Cold-rolled steel

also known as "Cold-formed steel" (CFS) or "cold worked steel" is any formed steel that is shaped in a processes carried out below recrystallization temperature (of steel). In raw material, like sheet metal, cold-rolled (in difference to "hot-rolled steel") usually describes how the metal was brought into the flat raw (sheet) shape. Shaping or "forming" can mean rolling to reduce thickness (as noted before), but also subsequent processes, like pressing in a press brake, punch press or stamping press, bending (folding) in a brake press or Cornice brake et cetera. Cold-forming usually leads to heightened strength and toughness but as steel in its various mixtures and alloys is graded in many aspects, the more colloquial terminology "cold-rolled steel" is often used as a marketing term to emphasize the robustness or strength of the used material in rack equipment. Cold rolled is one of many features to describe steel types and grades.Common Redundant Power Supply (CRPS)

CRPS is a backup power supply configuration with two or more power supply units working together - but only one being active at a time, and sharing a common interface and connector. Each unit must be capable of giving sufficient electrical power to the system. CRPS devices are commonly deployed in mission-critical environments - server rooms, data centers, and large network equipment environments.Commercial off-the-shelf

abbreviated as "COTS", sometimes varied as "commercially available off-the-shelf" is a term to describe products that are ready-made, don't need preparation or adaption prior to deployment and are usually easily available with short lead times. COTS is the opposite of tailor-made, custom-made, or bespoke solutions. Using a Blanking Panel, drilling and sawing an opening to it to build a DIY router mount would be using an "off-the-shelf" blanking panel to build a custom rack-mounting kit. One well known abbreviation related to COTS is "Mil-COTS", referring to COTS products for use by/ or used by the U.S. military.Converged Ethernet

Converged Ethernet (as part of the Data center bridging (DCB) initiative) is an improvement to the Ethernet protocol to improve its fitness for data center and enterprise use. Many Storage Area Network applications and the used protocols use UDP instead of a full TCP stack to improve performance. But Ethernet at its core is a "best effort" network, and UDP messages aren't guaranteed to arrive. Thus many SAN protocol implementations (e.g. RoCE in select versions) use some sort of mechanism to guarantee the arrival of messages as part of their protocol layer. Another approach now is to amend the underlying Ethernet layer in such a way that UDP messages are guaranteed to arrive. "Convergence Enhanced Ethernet" (or "Converged Enhanced Ethernet" (CEE)) is such an extension. But as these extensions are still in flux, it requires hardware equipment to be compatible.Console Drawer

Slide out combination of computer display, keyboard and trackball or mouse, usually designed in the form of a 1U or 2U rack mountable drawer. Most comnsole drawers are single screen but some designs offer multiple displays which slide out horizontally. Datacenter technicians can then stand in front of a rack and operate a console terminal without carrying a separate laptop or other terminal. A console drawer is an on-site local terminal solution (cmp. "Console Server" or "remote management").Console Server

also known as "console access server", "console management server", "serial concentrator", "serial console server" or "terminal server" is a device that connects to the RS232 serial port of networking (router, PBX), computer (servers) and enclosure management devices (PDUs, Rack management card) and tunnels their serial communication via Network (LAN, TCP/IP, or POTS/ "Plain Old Telephone System") to a remote management terminal ("Serial over IP"). While the more general term is "Terminal Server", in datacenter lingo the more common term is "Console Server" as the terminal server is commonly used only to connect to console ports (COM ports) of connected hosts and tunnel system DevOps sessions via Telnet or SSH ("remote console").Cornice brake