5.25-Inch Floppy Disk

The name "floppy" originates from the disk's flexible media - a circular, thin plastic film encased in a much thicker,

harder protective jacket. To allow a drive to rotate the disk within this jacket, both the outer jacket and the actual

disk have a large center hole, with a diameter slightly over 1 inch, for the drive spindle. This center hole is identical

on 8" and 5.25" disks. Often floppies feature a reinforcement collar to protect the hole from tearing and to prevent warping.

This design ensures the disk remains safe and stable when held by the clamping mechanism of a drive during insertion.

The first generation of floppy drives used 8-inch floppy disks and wrote on media with an iron oxide magnetic coating

with a track width of 0.330mm, resulting in 77 tracks at 48 tracks per inch (48 TPI). The media used was labeled with

Single Density. When Double Density was introduced, this didn't change track width, but meant that an improved line code

was employed to store more data per track. The designation Single or Double Density does not refer to a specific "density"

of the disk coating but instead to the density of data that is expected to be written and the quality level the produced

disk is expected to comply with.

The 5.25-inch next generation of floppy disks was introduced by Shugart Associates and was a shrunken version of the IBM

introduced 8-inch disk. (See also "Drive bay form-factors").

Despite the smaller form factor, such disks had the same pyhsical disk coating and drives wrote

with the same track width (48 tpi) to then only 35 tracks, due to the reduced surface area compared to an 8-inch disk.

Both, the new disk form-factor and the Shugart 34-pin interface quickly became a de-facto industry standard. One minor

optimisation was the increase in cylinders from initially 35 to later 40 tracks. While still written at 48 tpi, this

maxed out use of the available disk surface. Disks made for the initial 35 tracks only had a smaller R/W-window and would

not work in a drive expecting to write 40 tracks - but these disks are rare.

Later generations of drive mechanics which were able to provide higher accuracy and "double stepping" were able to double

the track density and write 96 tracks per inch, 80 tracks per disk side. In 1984 IBM introduced High Density disks which

used a different magnetic coating with higher coercivity, which meant that magnetic regions could be packed denser without

affecting each other - but that, in turn, required a different read/write-head which needed to be able to excert a higher

magnetic force. Although double density media could then be formatted by a HD drive, data written was usually stored

unreliably. In every day use, this often confused consumers and similar misunderstandings happened with the successor

3.5" Floppy Disk format and the difference between DD and HD media.

Earlier Micropolis floppy disk drives ("MegaFloppy") extended Shugart's standard of 48

tpi (tracks per inch) and increased track count to 77 tracks on a disk, and, with 100 TPI track density, doubled the

available storage on a disk. This Micropolis format was effectively a 1:1 scaled-down version of an 8-inch disk.

A next step was to also raise recording density in the "MetaFloppy" series of drives.

While the industry's step from single to double densitity didn't change track width, but doubled capacity by replacing

FM data encoding with MFM, the Micropolis "quad density" drive technology combined a doubled track count and replaced

MFM data encoding with GCR to make four times as much total storage available on a single 5.25-inch floppy disk. The

recording media used was still Double Density and write heads used the lower 300-oersted magnetic force (vs. the

600-oersted needed to write to HD media).

Despite a number of manufacturers (Tandon , Commodore, both in earlier

systems) adopting the 100TPI standard, Micropolis later switched to 96TPI when "double stepping" drives based on a

doubling of Shugart's 48TPI won out.

5.25-inch media was available as "single density" SD (1D) and the more common "double density" DD (2D). Both of these

designations were generally identical to those of 8-inch disks.

Quad density (QD or 4D) doubles capacity over DD by narrowing the width of tracks to 0.160 mm (0.0063 in) for a density

of 96 tpi. As explained here, Micropolis (and some other manufacturers, Tandon, Micro Peripherals (MPI), TEAC) used a track

density of 100 tpi to reach "Quad Density" in their drives.

High density (HD) on the other hand, improves capacity by utilizing a 96 tpi track density in conjunction with improved

cobalt disk coating and stronger 600-oersted write heads, allowing 9646 bpi to be written. This slightly wider track

spacing was incompatible with Micropolis' inital Quad Density track stepping, but when the 96 tpi standard won out in customer

adoption, Micropolis started offering 96 tpi drive versions in 1980 (Micropolis 1015-V and 1015-VI, Micropolis 1016-V 1016-VI).

Compare 1015/1016-family notes.

One thing to note about the step from 40 to 80 tracks refers to backwards compatibility. 80 track drives usually can read

floppies written by 40 track drives but not vice versa. This is because 40 track drives use write heads twice the width

of those used in 80 track drives. This leads to 40 track drives writing "broader" magnetic tracks, which the finer head of

a 80 track drive can read, but in turn, the "thinner" lines of a 80 track drive, although possibly written at a tpi resolution

of 40 tracks, wouldn't be picked up reliably by a true 40 track drive.

Hard-sectored vs. soft-sectored disks

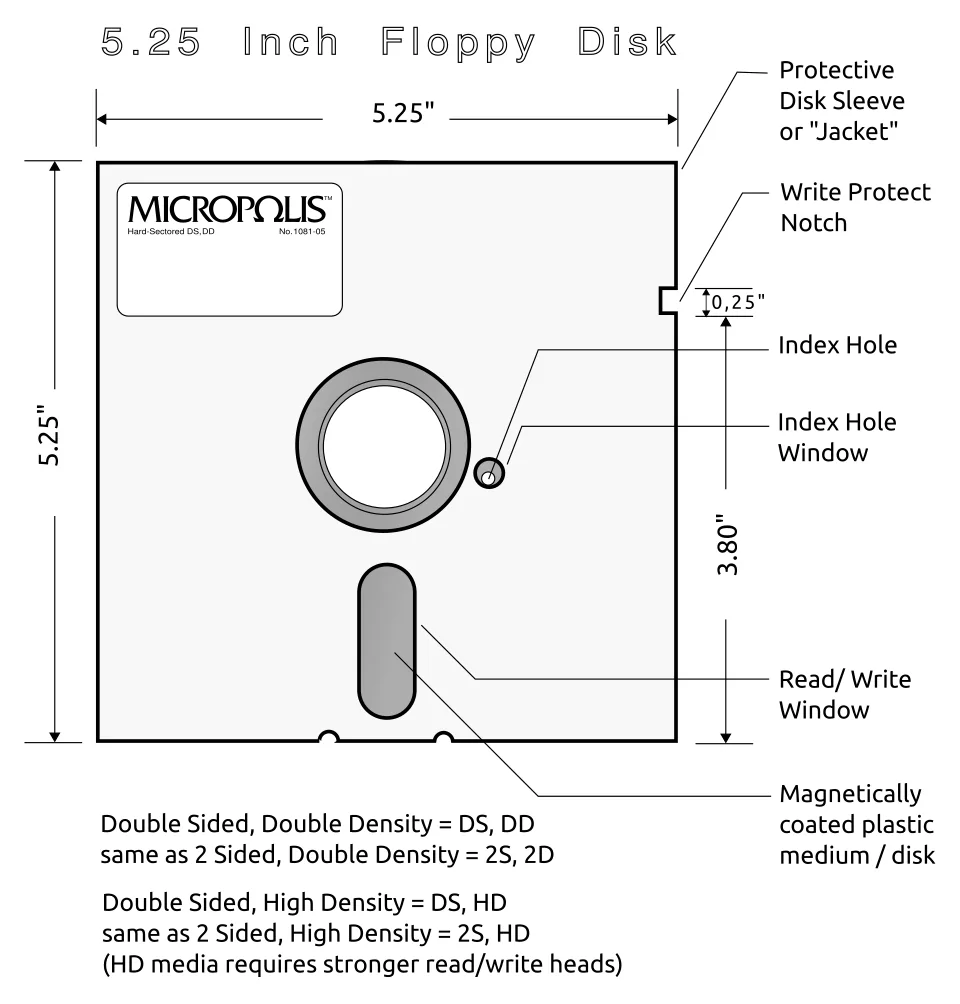

Most Micropolis floppy disk drives, especially earlier models, did not use "soft-sectored" media, but disk media that was hard-sectored. For example the Micropolis provided floppy disk with order no. 1081-05. A hard-sectored floppy disk is a disk with sector marking holes punched through the magnetic medium in circular arrangement around the center hub of the disk, with each hole marking the beginning of a sector. For 5.25" disks, there were hard-sectored disks with 10 sectors and, more commonly, 16 sectors. An optical sensor uses a small window in the disk's sleeve to pick up these holes and detect the beginning of one disk sector. An additional 17th index hole (or 11th for 10 sector media) is located halfway between the holes for sector 15 and sector zero. All these holes usually have a diamter of around 0.1 inches, or just a little over 2.5mm. These hole diameters were also used on the predecessor large 8" disks.

Later drives, and the later industry standard, is what is named "soft-sectored" media. A soft-sectored disk omits the sector holes and keeps only one hole, the 17th hole mentioned above, the index hole. The window in the disk's sleeve thus is usually called the "index hole". The same photosensor logic inside the drive detects this hole to mark one full rotation of the disk media inside the sleeve. The physically punched hard sector markers in soft sectored media were "moved into software", replaced by a special bit pattern that is written on disk during low level formatting of the disk.

With hard- or soft-sectored disks, it's important to understand that in these early days the drive mechanics itself knew little about how data was laid out onto the magnetic surface. Similarly as with MFM hard disks, such semantics were delegated to the attached controller. The drive's controller board was responsible for the disk format used. The "drive" was only mechanics, delegating head-positioning and motor control to the controller, which was also responsible for the data format written to disk. Early controllers were built on TTL eletronics and used hard-sectoring to locate reagions on disk. Later drives, built around IC-based controllers, relied less on sector marks but instead wrote marks into the data stream. What remained is the index hold that signalled one complete turn of the disk.

Hard-sectored media has its origins in 8-inch floppy disks and was carried over to the smaller 5.25" format for some time. Micropolis' use of hard-sectored media has its root in the early Micropolis 100085-01-8A floppy drive controller board and later 1071 controller, which both used logics built for hard-sectored media.

Key takeaways:- 5 and a quarter disks are mostly just a miniaturization of 8 inch floppy disks. Both were initially single sided and used the same iron oxide coating. Both started with hard-sectored formatting and later switched to a soft-sectored layout.

- There is no significant difference in the magnetic coating material between SD ("single density") and DD ("double density") floppy disks. Also, coercivity of the used coating is the same or very similar. Double Density disks simply needed to be of higher quality and more tightly tolerated to reliably store the denser data. And the density of written data is actually what usually differs.

- 3.5" Floppy Disk

- MFM hard disks

- SMR Disk Drives

- HAMR Disk Drives

- and from our our Data Storage Glossary the section on "Drive-bay-Form-factors"